Former BCIT students make thousands of PPE items at home for local health-care workers

Two BCIT alumni are using 3-D printers at home to manufacture thousands of pieces of personal protective equipment (PPE) for local frontline health-care workers.

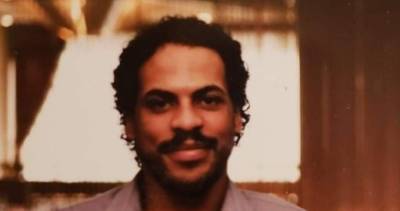

Keisha Go amd Jamie Haakons—graduates of BCIT's interior-design and mechanical-engineering programs, respectively—started thinking about making PPE after a pre-lockdown trip to the Philippines.

After designing prototypes and turning out the first batches of face shields and ear savers (used to prevent skin irritation from face-mask straps) to be sent from their Coquitlam residence to the Philippines, they learned that international shipments to that country had been halted.

After hearing of local PPE shortages for frontline workers, they decided to seek out extra 3-D printers from friends and other donors to turn out PPE from a converted room in their home. They ended up with eight printers working full-time, producing about 100 face shields and 200 ear savers each day.

"In response to the shortage of PPE, some of our health-care workers are innovating by wearing swimming goggles and bike helmets with transparency sheets glued in front," Haakons said in a April 29 BCIT release. "Hearing these stories motivated us to work harder to help the community."

To date, they have made more than 6,500 items that have been distributed to Vancouver General Hospital, the B.C. Cancer Agency, Surrey Memorial Hospital, Royal Columbian Hospital, the Burnaby Division of Family Practice, the GF Strong Rehabilitation Centre, and other facilities.

"As BCIT students, we were challenged, but in a positive way," Haakons said. "BCIT programs are not easy and the bar is set very high. Through this, we developed strong work ethics and great problem-solving skills, so issues that arose with this project did not seem that hard to fix."

Comments